One of the funnest events in cub scouting is the pinewood derby. Below are free plans to pinewood derby cars I have found to be very successful. My personal recommendation is the Flying Wedge. It is not the prettiest car, but I think it has the best chance of winning (which, of course, is not everything). Before you begin your car, be sure to see our page on Speed and Construction Tips. Feel free to ask questions about the plans. I would love to post pictures of your car in the Pinewood Derby Photo Gallery, just send them to pinewood@boysdad.com.

Car Designs

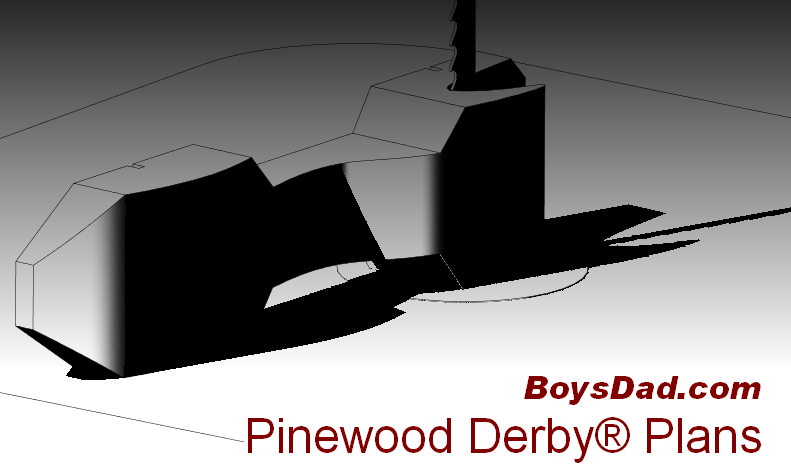

All of these plans are completely free and are designed for easy cutting with an ordinary bandsaw with a narrow blade. Please NEVER allow a child to operate a bandsaw.

Each car design has 2 files associated with it. 1) An engineering drawing with accurate mass properties, and 2) a template that you can trace onto the pine block as a cutting guide. The links for both files appear below the picture. You can click the picture for a larger view of the design.

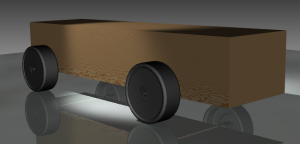

Blank Car Template

This is a full size template of the current Pinewood Derby® block that will allow you to design your own car style. The axle slots and an outline of the wheels are included. This insures you will have a unique design.

This is a full size template of the current Pinewood Derby® block that will allow you to design your own car style. The axle slots and an outline of the wheels are included. This insures you will have a unique design.

(blank.pdf, Full-Size Template)

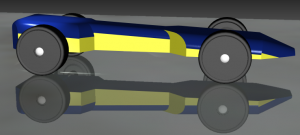

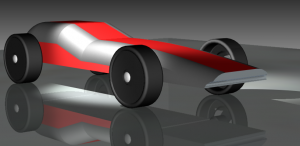

Car Style “Bond”

Taking design cues from winning Indy car models, Bond offers a combination of style and speed that is hard to beat. The rear of the car offers generous room to drill for lead or tungsten weights, while the front is an aerodynamic wedge that cuts through the wind like a knife.

Taking design cues from winning Indy car models, Bond offers a combination of style and speed that is hard to beat. The rear of the car offers generous room to drill for lead or tungsten weights, while the front is an aerodynamic wedge that cuts through the wind like a knife.

(Bond1.pdf, Full-Size Template)

Car Style “Fonz”

Definitely a showstopper. With its high rear spoiler and aerodynamic styling the Fonz looks like it is ready to take on the toughest competition. The Fonz allows for a rearward weight distribution concentrated just forward of the rear wheels.

Definitely a showstopper. With its high rear spoiler and aerodynamic styling the Fonz looks like it is ready to take on the toughest competition. The Fonz allows for a rearward weight distribution concentrated just forward of the rear wheels.

(fonz.pdf , Full-Size Template)

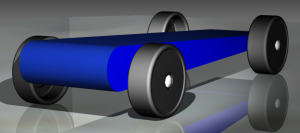

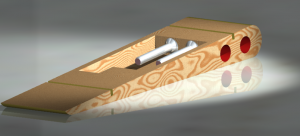

Car Style “Flying Wedge”

Short on style but built for pure speed the Flying Wedge is the car I have won more races with than any other. The style of this car has evolved over the past several years into an extremely consistent performer. With near perfect rearward weight distribution and adjustable weight lugs, the Flying Wedge allow for last minute weight adjustment that is critical to winning.

Short on style but built for pure speed the Flying Wedge is the car I have won more races with than any other. The style of this car has evolved over the past several years into an extremely consistent performer. With near perfect rearward weight distribution and adjustable weight lugs, the Flying Wedge allow for last minute weight adjustment that is critical to winning.

NEW – by Popular Demand: CLICK HERE FOR Full Build Instructions for the Flying Wedge

(drawing & Full-Size Template)

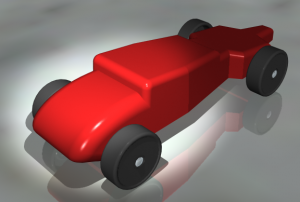

Car Style “Hot Rod”

With styling reminiscent of a 33 coupe, the Hot Rod is a real beauty. This car can be a real heart throb when you take the time to sand the curves smooth. If you are a real craftsman, the Hot Rod can be a real work of art.

With styling reminiscent of a 33 coupe, the Hot Rod is a real beauty. This car can be a real heart throb when you take the time to sand the curves smooth. If you are a real craftsman, the Hot Rod can be a real work of art.

(hotrod.pdf, Full-Size Template)

Car Style “Luthor”

The real “bad boy” of the racetrack, Luthor brings ’70s styling to the modern Pinewood track. Luthor is another car that is built for speed. Many of the enhancements that the Flying Wedge uses can be incorporated into the Luthor body style.

The real “bad boy” of the racetrack, Luthor brings ’70s styling to the modern Pinewood track. Luthor is another car that is built for speed. Many of the enhancements that the Flying Wedge uses can be incorporated into the Luthor body style.

(luthor1.pdf, Full-Size Template)

49 comments for “Pinewood Derby® Plans”